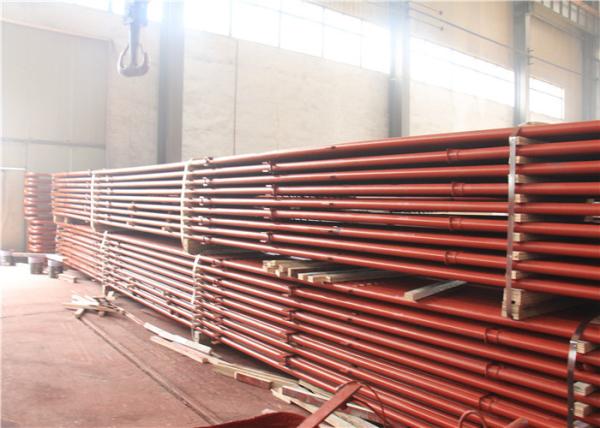

Carbon steel seamless Boiler Pipe,low carbon annealed ASTM A179

Gr.B, Min. Wall Thickness, U Bend pipe

Seamless cold-drawn annealed pipe for tubular heat exchangers,

condensers, and similar heat transfer apparatus.This pipe shall be

made by the cold drawn process.

Chemistry Composition:

C, % | Mn, % | P, % | S, % |

0.06-0.18 | 0.27-0.63 | 0.035 max | 0.035 max |

Mechanical Properties:

Tensile Strength, MPa | Yield Strength, MPa | Elongation, % | Hardness, HRB |

325 min | 180 min | 35 min | 72 max |

A179 black steel pipe minimum carbon content is 0.06%. The seamless

steel tube minimum tensile strength of 325MPa, yield strength of

180MPa.The minimum elongation of A179 seamless pipe is 20%.

ASTM A179 Steel Pipes Application:

A179 seamless steel pipe is widely used in industries such as

petroleum, chemical, medical, food, light industry, machinery,

instrument, include industrial pipeline and mechanical structure

parts, etc.

Standard:ASTM A179

Delivery time : Promptly ( Stock) or 10-40 days (Production) Stock

: some are Available MTC: Available

Main ASTM A179 (ASME SA179) cold drawn steel tube:

This is an effective way of metal corrosion, the use of the main

features are the following:

1. ASTM A179 cold drawn seamless pipe manufacturers with thick

dense dense zinc layer covered in the cold drawn seamless tube

surface, it can avoid cold drawn seamless tube matrix and any

contact with the corrosion solution to protect the steel matrix

from corrosion. In the general atmosphere, the surface of the zinc

layer to form a layer of thin and dense zinc oxide surface, it is

difficult to dissolve in water, so the steel matrix plays a

protective role. If zinc oxide and other components of the

atmosphere produce insoluble zinc salt, the anti-corrosion effect

is more desirable.

2. With iron - zinc alloy layer, combined with dense, and with the

unique anti-corrosion in the marine atmosphere and atmospheric

atmosphere.

3. ASTM A179 cold drawn seamless pipe with a strong wear resistance

due to the combination of solid, zinc - iron miscible.

4. Since zinc has good ductility, its alloy layer and steel base

attached to a solid, so hot-rolled parts can be cold, rolling,

drawing, bending and other molding without damage to the coating.

5. Hot-dip galvanized structural steel pipe, the equivalent of an

annealing treatment, can effectively improve the mechanical

properties of steel matrix to eliminate the steel forming welding

stress, is conducive to the steel structure for turning.

6. The surface of cold drawn seamless pipe after hot galvanized is

bright and beautiful.

7. Pure zinc layer is the most hot galvanized layer of galvanized

layer, its nature is basically close to pure zinc, with ductility,

so it is full of flexibility.

Outside Diameter & Tolerance

Outside Diameter, mm | Tolerance, mm |

3.2≤OD<25.4 | ±0.10 |

25.4≤OD≤38.1 | ±0.15 |

38.1<OD<50.8 | ±0.20 |

50.8≤OD<63.5 | ±0.25 |

63.5≤OD<76.2 | ±0.30 |

76.2 | ±0.38 |

Wall thickness & Tolerance

Outside Diamter, mm | Tolerance, % |

| 3.2≤OD<38.1 | +20/-0 |

38.1≤OD≤76.2 | +22/-0 |

Length: 5800mm; 6000mm; 6096mm; 7315mm; 11800mm; and so on.

Max length: 27000mm, also U bending can be offered.

Seamless cold-drawn tube for tubular heat exchangers, condensers,

and similar heat transfer apparatus.This pipe shall be made by the

cold drawn process.

Chemistry Composition:

C, % | Mn, % | P, % | S, % |

0.06-0.18 | 0.27-0.63 | 0.035 max | 0.035 max |

Mechanical Properties:

Tensile Strength, MPa | Yield Strength, MPa | Elongation, % | Hardness, HRB |

325 min | 180 min | 35 min | 72 max |

A179 black steel pipe minimum carbon content is 0.06%. The seamless

steel tube minimum tensile strength of 325MPa, yield strength of

180MPa.The minimum elongation of A179 seamless pipe is 20%.

ASTM A179 Steel Pipes Application:

A179 seamless steel pipe is widely used in industries such as

petroleum, chemical, medical, food, light industry, machinery,

instrument, include industrial pipeline and mechanical structure

parts, etc.

Standard:ASTM A179

Delivery time : Promptly ( Stock) or 10-40 days (Production) Stock

: some are Available MTC: Available

Main ASTM A179 (ASME SA179) cold drawn steel tube:

This is an effective way of metal corrosion, the use of the main

features are the following:

1. ASTM A179 cold drawn seamless pipe manufacturers with thick

dense dense zinc layer covered in the cold drawn seamless tube

surface, it can avoid cold drawn seamless tube matrix and any

contact with the corrosion solution to protect the steel matrix

from corrosion. In the general atmosphere, the surface of the zinc

layer to form a layer of thin and dense zinc oxide surface, it is

difficult to dissolve in water, so the steel matrix plays a

protective role. If zinc oxide and other components of the

atmosphere produce insoluble zinc salt, the anti-corrosion effect

is more desirable.

2. With iron - zinc alloy layer, combined with dense, and with the

unique anti-corrosion in the marine atmosphere and atmospheric

atmosphere.

3. ASTM A179 cold drawn seamless pipe with a strong wear resistance

due to the combination of solid, zinc - iron miscible.

4. Since zinc has good ductility, its alloy layer and steel base

attached to a solid, so hot-rolled parts can be cold, rolling,

drawing, bending and other molding without damage to the coating.

5. Hot-dip galvanized structural steel pipe, the equivalent of an

annealing treatment, can effectively improve the mechanical

properties of steel matrix to eliminate the steel forming welding

stress, is conducive to the steel structure for turning.

6. The surface of cold drawn seamless pipe after hot galvanized is

bright and beautiful.

7. Pure zinc layer is the most hot galvanized layer of galvanized

layer, its nature is basically close to pure zinc, with ductility,

so it is full of flexibility.

Outside Diameter & Tolerance

Outside Diameter, mm | Tolerance, mm |

3.2≤OD<25.4 | ±0.10 |

25.4≤OD≤38.1 | ±0.15 |

38.1<OD<50.8 | ±0.20 |

50.8≤OD<63.5 | ±0.25 |

63.5≤OD<76.2 | ±0.30 |

76.2 | ±0.38 |

Wall thickness & Tolerance

Outside Diamter, mm | Tolerance, % |

| 3.2≤OD<38.1 | +20/-0 |

38.1≤OD≤76.2 | +22/-0 |

Length: 5800mm; 6000mm; 6096mm; 7315mm; 11800mm; and so on.

Max length: 27000mm, also U bending can be offered.

Seamless cold-drawn tube for tubular heat exchangers, condensers,

and similar heat transfer apparatus.This pipe shall be made by the

cold drawn process.

Chemistry Composition:

C, % | Mn, % | P, % | S, % |

0.06-0.18 | 0.27-0.63 | 0.035 max | 0.035 max |

Mechanical Properties:

Tensile Strength, MPa | Yield Strength, MPa | Elongation, % | Hardness, HRB |

325 min | 180 min | 35 min | 72 max |

A179 black steel pipe minimum carbon content is 0.06%. The seamless

steel tube minimum tensile strength of 325MPa, yield strength of

180MPa.The minimum elongation of A179 seamless pipe is 20%.

ASTM A179 Steel Pipes Application:

A179 seamless steel pipe is widely used in industries such as

petroleum, chemical, medical, food, light industry, machinery,

instrument, include industrial pipeline and mechanical structure

parts, etc.

Standard:ASTM A179

Delivery time : Promptly ( Stock) or 10-40 days (Production) Stock

: some are Available MTC: Available

Main ASTM A179 (ASME SA179) cold drawn steel tube:

This is an effective way of metal corrosion, the use of the main

features are the following:

1. ASTM A179 cold drawn seamless pipe manufacturers with thick

dense dense zinc layer covered in the cold drawn seamless tube

surface, it can avoid cold drawn seamless tube matrix and any

contact with the corrosion solution to protect the steel matrix

from corrosion. In the general atmosphere, the surface of the zinc

layer to form a layer of thin and dense zinc oxide surface, it is

difficult to dissolve in water, so the steel matrix plays a

protective role. If zinc oxide and other components of the

atmosphere produce insoluble zinc salt, the anti-corrosion effect

is more desirable.

2. With iron - zinc alloy layer, combined with dense, and with the

unique anti-corrosion in the marine atmosphere and atmospheric

atmosphere.

3. ASTM A179 cold drawn seamless pipe with a strong wear resistance

due to the combination of solid, zinc - iron miscible.

4. Since zinc has good ductility, its alloy layer and steel base

attached to a solid, so hot-rolled parts can be cold, rolling,

drawing, bending and other molding without damage to the coating.

5. Hot-dip galvanized structural steel pipe, the equivalent of an

annealing treatment, can effectively improve the mechanical

properties of steel matrix to eliminate the steel forming welding

stress, is conducive to the steel structure for turning.

6. The surface of cold drawn seamless pipe after hot galvanized is

bright and beautiful.

7. Pure zinc layer is the most hot galvanized layer of galvanized

layer, its nature is basically close to pure zinc, with ductility,

so it is full of flexibility.

Outside Diameter & Tolerance

Outside Diameter, mm | Tolerance, mm |

3.2≤OD<25.4 | ±0.10 |

25.4≤OD≤38.1 | ±0.15 |

38.1<OD<50.8 | ±0.20 |

50.8≤OD<63.5 | ±0.25 |

63.5≤OD<76.2 | ±0.30 |

76.2 | ±0.38 |

Wall thickness & Tolerance

Outside Diamter, mm | Tolerance, % |

| 3.2≤OD<38.1 | +20/-0 |

38.1≤OD≤76.2 | +22/-0 |

Length: 5800mm; 6000mm; 6096mm; 7315mm; 11800mm; and so on.

Max length: 27000mm,

U bend pipe size can be customized.